First delivery of new cable packaging system

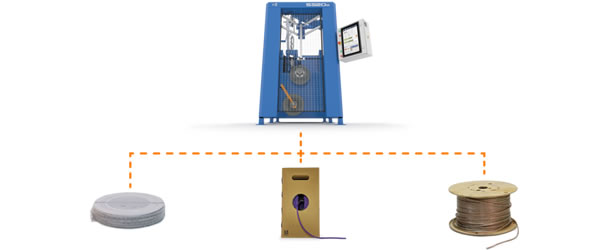

Reelex Packaging Solutions, an innovator in sustainable wire and cable packaging technology, has delivered its first S320e machine model and Payoff-Dancer (POD) system to a global wire and cable manufacturer. The solution is designed to enhance productivity, reduce environmental impact and improve both user experience and safety for cable manufacturers and distributors.

Introducing the first Reelex S320e and POD system to our customers is an important milestone,

said David Gerhart, CEO of Reelex. This launch represents the culmination of years of development and customer feedback, and we are confident it will provide unparalleled value and efficiency to the cable packaging industry. Our goal is to help our customers meet their sustainability targets while driving down costs, and the Reelex S320e does exactly that.

The machine uses the patented Reelex technology, which coils cable in a twist-free, tangle-free package, making it easier to transport, store and install. It also has the ability to wind on a traditional spool if preferred. In conjunction with the POD system, the S320e allows for flexibility in production, automating the packaging process to meet various customer requirements.

With a smaller footprint, faster cycle times and enhanced energy efficiency, the S320e model addresses growing demand for sustainable and reliable packaging solutions. The Reelex S320e with POD not only minimises the use of materials, but is also claimed to improve package consistency and durability, reducing damage and waste throughout the supply chain.

Cable manufacturers have been asking for a cost-effective solution that combines flexibility with reliability, and the Reelex S320e and POD system is clearly a winning combination,

said Mr Gerhart. This advanced technology is giving customers improvements in production efficiency by having options to run Reelex coiling and spools with infinite variations in packaging options. This provides one machine that allows for a growing packaging portfolio so that customers can switch out to spooling without changing out equipment.

The S320e features an intuitive interface that enables operators to program and adjust settings easily. It includes a simple step-by-step set-up process for each product changeover. The machine's enhanced automation and real-time monitoring capabilities ensure that each package meets precise specifications, resulting in fewer errors and less rework.