Rosendahl Nextrom

Booth: 301

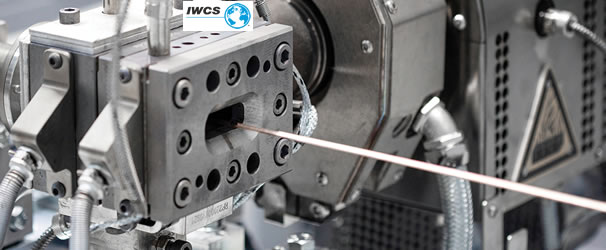

Continuing demand for high-speed data infrastructure places a focus of Rosendahl Nextrom's R&D work in this area. The company offers production lines for fibre optic and copper cables, optimised for high-speed production and equipped with features for scrap reduction, quality control and automation.

Rosendahl's high-temperature physical foaming lines can manufacture cables with unique properties in high-end applications such as medical or aerospace technology, or AI data centres.

For preform manufacturing, Nextrom has combined vapour axial deposition and outside vapour deposition technologies tailored to producing large-sized preforms. In addition, the telecom fibre drawing process has been optimised to reach speeds of up to 3,500m/min.

With batteries being used as the energy source in modern cars, vehicle wiring is changing. New types of cables and wires are needed for both propulsion and power distribution. Rosendahl has introduced a turnkey extrusion line for hairpin insulation that makes a safe and reliable power supply at 800V possible and minimises energy losses in electric board systems. Other solutions for the automotive industry include busbar insulation, high-end charging cables and high-performance data cables.

Rosendahl Nextrom's sustainable concept for forming, welding and jacketing flexible materials and product sizes on a single production line is suited to connecting wind farms, photovoltaic farms and offshore projects to the power grid.

A major focus of Rosendahl Nextrom's efforts is the thoughtful use of materials, waste reduction, minimising wear and enhancing energy efficiency. Its powerful line control offers a wide variety of possibilities to continuously improve production. ESG-compliant measurement of CO2 and energy consumption has been added to Rosendahl Nextrom's smart portfolio, ready to support the green transition in the industry. An AI-based process control further improves process stability and product quality for datacom cables.

In the field of telecom fibre drawing, Nextrom's Helium Recovery System recovers up to 90 per cent of the used helium, reducing dependence on this limited resource.